1.Working principle of garbage incinerator:

The working principle of rubbish incinerator is to decompose the combustible components in garbage into gas, liquid and residue through high-temperature combustion, while generating a large amount of heat. Its main process steps include:

● Garbage feeding:

Garbage enters the incinerator through conveyor belts, automatic feeding systems and other equipment. At this stage, large pieces of waste and debris in the garbage will be removed.

● Garbage drying:

The garbage entering the incinerator will first be dried at a lower temperature to remove the moisture in it. High-humidity garbage evaporates moisture through the hot air system of the incinerator to avoid affecting the incineration effect due to excessive moisture.

● Incineration process:

In the incinerator, by continuously heating to a high temperature of 800℃-1000℃, organic matter, plastics, paper, wood, etc. in the garbage will burn and generate heat. The combustion process is divided into primary combustion and secondary combustion:

Primary combustion: Garbage is initially burned in the incinerator to convert organic matter into gas (such as CO2, H2O) and combustible gas.

Secondary combustion: By injecting additional air or oxygen, the combustion is more complete, harmful substances in the exhaust gas (such as dioxins, nitrogen oxides, etc.) are eliminated, and the incineration efficiency is improved.

● Heat recovery:

The heat generated during the incineration process can be converted into steam, hot water or electricity through a heat exchange system. Steam can drive steam turbines to generate electricity, or be used for urban heating to form "cogeneration".

● Waste gas treatment:

During the incineration process, harmful substances in the exhaust gas (such as dioxins, nitrogen oxides, particulate matter, etc.) will be discharged into the air, so they need to pass through the exhaust gas treatment system. Common exhaust gas purification technologies include:

Wet scrubbing: Remove acidic gases and particulate matter from the exhaust gas through water spraying.

Activated carbon adsorption: Adsorb toxic gases (such as dioxins, hydrogen chloride, etc.) in the exhaust gas.

Denitrification device: Remove nitrogen oxides (NOx) from the exhaust gas.

● Residue treatment:

The residue (ash, slag, etc.) generated after incineration is treated by processes such as cooling, screening and sorting. Some of the residue can be used as building material or landfilled, while other residues need to be disposed of through landfill.

2.Types of waste incinerators:

The most common type of waste incinerator is a grate incinerator, which uses an inclined grate to support the burning of the waste. The waste moves slowly forward through the grate, and the combustion gases on the waste are gradually ignited and release heat. There is often a secondary combustion chamber above the grate to ensure the completeness of the combustion process.

The design of the rotary kiln incinerator is similar to a rotating cylinder, and the garbage moves in the furnace as the drum rotates. The high-temperature airflow allows the garbage to be completely burned, while avoiding garbage accumulation or incomplete combustion.

Gasifiers heat garbage to high temperatures in an oxygen-deficient environment, breaking it down into combustible gases (such as syngas), which can be used as fuel for power generation or heating.

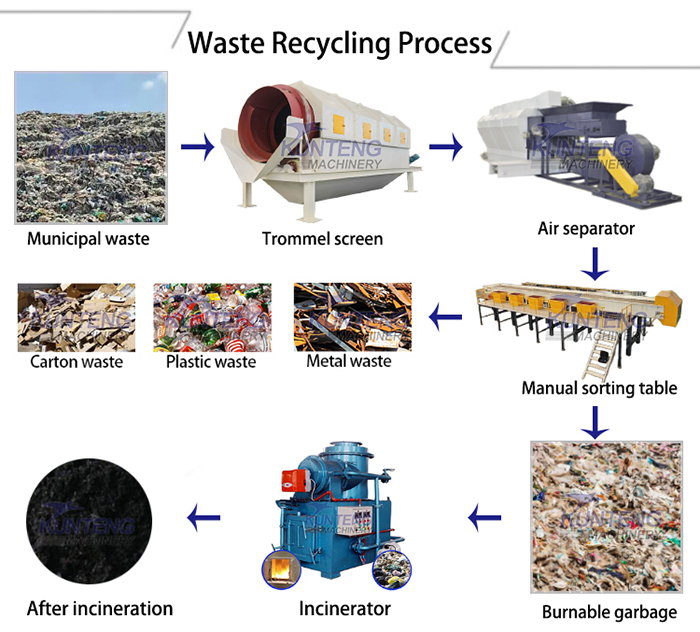

3.Waste treatment production line process

4.Advantages of dustbin incinerator:

● Volume Reduction: Incineration reduces the volume of waste by up to 90%, significantly lowering the need for landfill space.

● Energy Recovery: The heat generated from burning waste can be converted into electricity or used for heating, contributing to energy generation.

● Lower Landfill Use: By treating waste via incineration, the reliance on landfills is reduced, alleviating environmental pressure and the risk of groundwater contamination.

● Reduction of Hazardous Waste: Incineration destroys hazardous components of waste, such as certain chemicals and pathogens in medical or industrial waste, preventing environmental contamination.

Garbage incinerators play a critical role in modern waste management systems, particularly in urban areas with limited landfill capacity. They help reduce waste volume, recover energy, and safely treat hazardous materials. However, careful management and advanced technology are essential to mitigate environmental impacts, such as air pollution. As part of an integrated waste management strategy, incineration can be a valuable tool, especially when combined with recycling and composting programs.