Domestic waste disposal machine is intelligent.The domestic waste sorting system adopts first-class design concepts and manufacturing processes.Domestic garbage sorting m...

Phone:0086 17596531123

The domestic waste sorting production line is a comprehensive equipment system that integrates a variety of advanced technologies, aiming to efficiently and environmentally friendly process the large amount of waste generated in urban life. The following is a detailed analysis of the domestic waste sorting production line:

1. Main components

Domestic waste sorting production lines usually consist of the following main links:

Waste reception and pretreatment:

Receive mixed domestic waste from various collection points.

Through physical treatment such as crushing and screening, the volume of waste is reduced to facilitate subsequent sorting and processing.

Fine sorting:

Use advanced sensors, image recognition technology and equipment such as robotic arms to accurately identify and classify waste.

Common classifications include recyclables (such as paper, plastics, metals, etc.), hazardous waste (such as batteries, fluorescent tubes, etc.), wet waste (such as kitchen waste) and dry waste.

Resource recycling:

The sorted recyclables will be sent to a special recycling and processing center for reuse.

For example, plastics can be recycled into new plastic products, and metals can be recycled and re-refined.

Final treatment:

For waste that cannot be recycled, the production line will use incineration, landfill or other environmentally friendly methods for harmless treatment.

Ensure that the waste does not cause secondary pollution to the environment.

2. Core equipment and technology

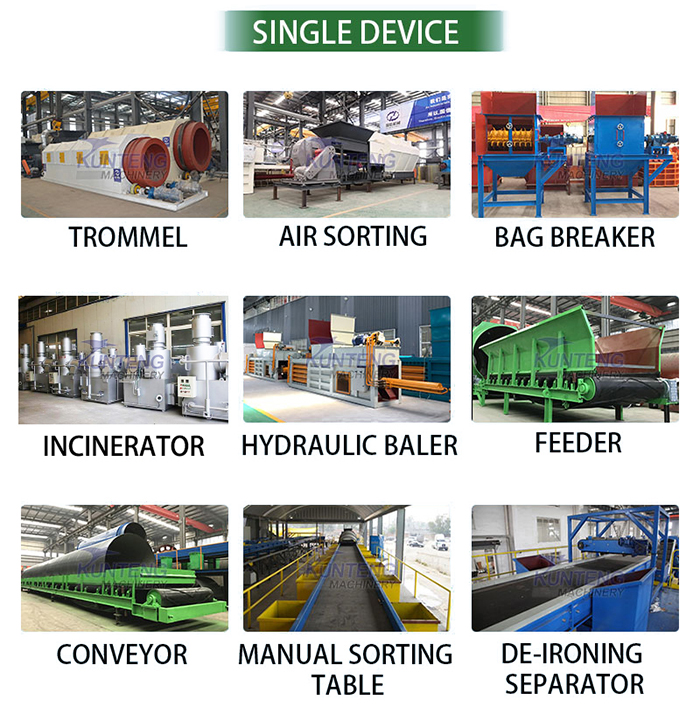

The core equipment and technology of the domestic waste sorting production line include:

Automatic bag breaker:

It is used to shake the garbage in the garbage bag onto the sorting equipment for subsequent crushing and separation.

Crusher:

It is used to crush large pieces of garbage, such as furniture, electrical appliances, tires, etc., for subsequent separation and recycling.

There are many types of crushers, such as shear type, impact type, jaw type, etc.

Sorting equipment:

This is the heart of the garbage sorting equipment production line, responsible for sorting garbage.

Common sorting equipment includes manual sorting table, vibrating screen, wind sorter, magnetic separator, etc.

These equipment can be selected and combined according to the characteristics and processing requirements of the garbage.

Sensor and image recognition technology:

The image of the garbage is captured by a high-resolution camera, and the image is analyzed using a deep learning algorithm to identify the type of garbage.

Robotic arm and conveyor belt:

Based on the recognition results, the robotic arm or conveyor belt will send the garbage to the corresponding collection area.

3. Technical features and advantages

The domestic waste sorting production line has the following technical features and advantages:

High efficiency:

The production line adopts automation and intelligent technology, which greatly improves the efficiency of waste treatment and shortens the treatment cycle.

Environmental protection:

Through fine sorting and resource recycling, the amount of landfill and incineration is reduced, and the pollution to the environment is reduced.

Intelligence:

The production line is equipped with advanced sensors and image recognition technology, which can automatically identify different types of garbage and classify them for treatment.

Resource utilization:

The recycling rate of recyclables is improved, and the recycling and sustainable development of resources are promoted.

The uses of domestic waste sorting production line are mainly reflected in the following aspects:

1. Improve the efficiency of garbage sorting

The domestic garbage sorting production line can efficiently sort and process garbage through automated and intelligent sorting equipment. Compared with the traditional manual sorting method, the production line not only improves the sorting speed, but also reduces labor costs. At the same time, the automated sorting process reduces the sorting errors caused by human factors and improves the accuracy of sorting.

2. Promote resource recycling

Domestic garbage contains a large amount of recyclable resources, such as paper, plastic, metal, etc. Through the sorting production line, these resources can be effectively separated and utilized. This can not only reduce the waste of resources, but also reduce the cost of garbage disposal, while promoting the development of the circular economy.

Kunteng company was founded in 1999, we are professional manufacture: domestic waste disposal machine, domestic waste sorting system, domestic garbage sorting machine project,etc. Reuse materials to reduce pollution and have goodsustainability.Machinery has cooperated with manymanufacturers in China and other countries to providemachinery equipment for the production lines of manymanufacturers. Machinery pays attention to customerapplicabilityand product research and development, andthe level of production skills is perfect.

Henan Kunteng Machinery Manufacturing Co., Ltd

Address:No. 9 Yulian Industrial Cluster, Gongyi, Zhengzhou, Henan Province China

Phone:0086 17596531123