Combustible waste shredding RDF briquetting production line is widely used.Combustible garbage shredding RDF briquetting production line is environmentally friendly,combu...

Phone:0086 17596531123

1.RDF briquettes making machine

An RDF briquettes making machine is a machine designed to convert Refuse-Derived Fuel (RDF) into briquettes. RDF is a type of fuel derived from waste materials, typically non-recyclable plastics, paper, and other organic materials, and is commonly used as an alternative energy

source. Briquettes are compact, solid blocks of compressed material that are easier to handle, store, and transport than loose RDF.

2.The Process:

Collection and Sorting: Waste materials are first collected and sorted. Non-recyclable materials (plastics, paper, etc.) are separated from recyclables, and impurities (such as metals or glass) are removed.

Shredding and Grinding: The remaining RDF materials are shredded into smaller pieces or ground into a fine powder to make them more manageable for the briquetting process.

Drying: If the RDF has high moisture content, it is dried to ensure that the briquettes will burn effectively.

Compression into Briquettes: The processed RDF is then fed into a briquetting machine, where it is compressed under high pressure to form uniform briquettes. This step may involve adding a binder (like starch or other organic adhesives) to help the material hold its shape.

Cooling and Packaging: After briquetting, the briquettes are cooled and packaged for storage and transportation.

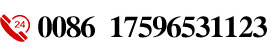

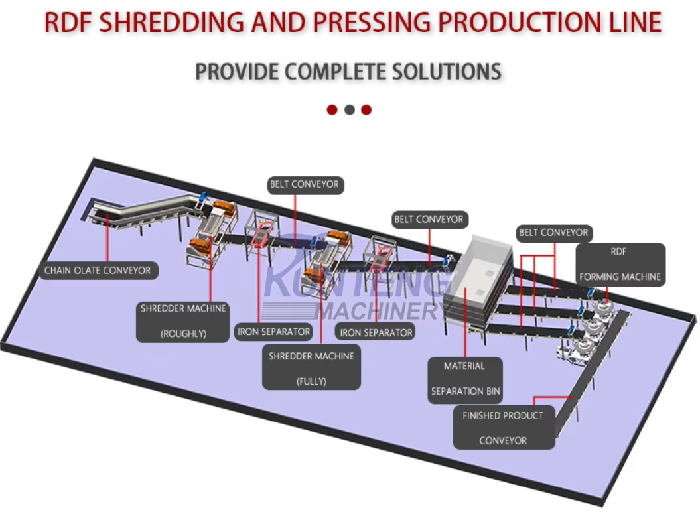

3.Main process description of waste sorting line:

1. Loading MSW to the box feeder machine;

2. Trommel screen separates MSW into organic matter and non-organic materials;

3. The non-organic materials passes through the air sorting system, which separates the materials into heavy and light materials;

4. Heavy and light materials are separately conveyed to the manual sorting table for precise sorting;

5. The sorted light materials can be made into fuel rods to replace traditional fossil fuels, reduce carbon dioxide emissions, and promote the achievement of carbon neutrality goals

4.Main machines of the line

1)Trommel screen

Trommel screen is used to separate MSW into organic waste and non-organic waste. The organic waste will be screened out under the screen. The non-organic waste will move forward to the next machine.

The diameter of trommel screen can be customized from 30 to 200 mm, and the diameter of trommel screen for municipal solid waste is usually 50 mm.

2)Air sorting machine

This air sorting machine can out heavy substances (such as stones, glass bottles) and light substances (can bottles, plastic, paper, etc.), with lower power, lower noise, large processing capacity, and high efficiency.

The air sorting system is stable and reliable, easy to maintain, and the sorting efficiency can reach more than 95%.

3)Sherrder machine

The shredder is a machine used for fine crushing, generally used to process unprocessed raw materials or scraps to make them smaller in size. Easy to reprocess and reuse

4)RDF briquettes making machine

RDF fuel rod machines can process materials such as household waste, waste plastics, waste cloth strips, and waste paper. The fuel rods produced have the characteristics of high calorific value, stable fuel, easy storage, and convenient transportation. They are widely used in industries such as drying engineering, heating engineering, and power generation, bringing vitality to the resource utilization of waste.

5.Company Introduction

Kunteng Machinery is established in 1999 and is located in Zhengzhou City, Henan Province, China. We are a comprehensive enterprise integrating R&D, production, sales, and service.

With independent R&D team, our own factory, and professional sales and service departments, we can manufacture high-quality combustible waste shredding RDF briquetting production line, combustible garbage shredding RDF briquetting production line, combustible rubbish shredding RDF briquetting production line,etc for our customers.

Henan Kunteng Machinery Manufacturing Co., Ltd

Address:No. 9 Yulian Industrial Cluster, Gongyi, Zhengzhou, Henan Province China

Phone:0086 17596531123