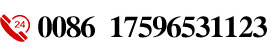

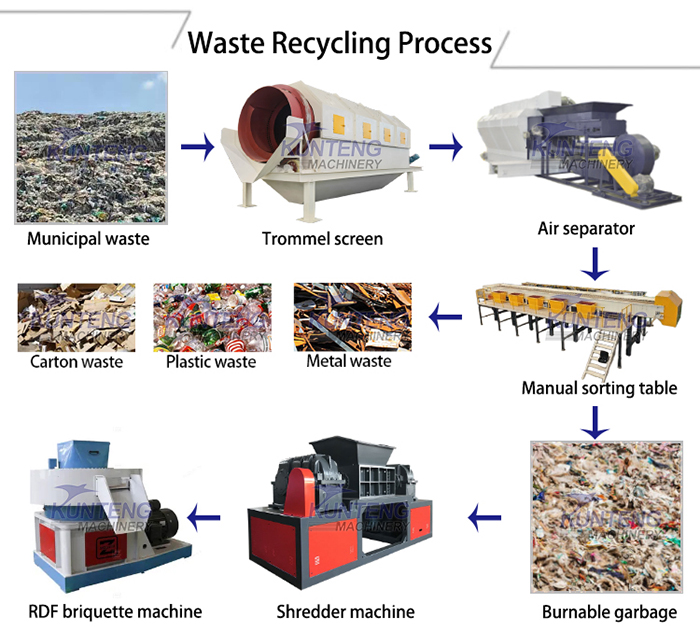

1. Production line composition

The industrial waste shredding production line mainly consists of the following parts:

Feeding and conveying equipment: such as grabbers or conveyor belts, used to feed raw materials into the production line.

Drum screening machine: Through the rotation and throwing of the drum, impurities such as sand and soil in the raw materials are screened out.

Spiral blade propeller: used to push the larger clean materials after screening forward.

Manual sorting platform: Workers select large pieces of plastic, metal, wood, etc. in the raw materials.

Strong magnetic iron remover: used to further sort out the metal that has not been sorted out.

Shredder: Cut, tear and crush the raw materials to the expected particle size.

Simple air separator: used for simple separation of light plastics and large pieces of plastics.

Hydraulic baler: Bale the separated large pieces of light plastics.

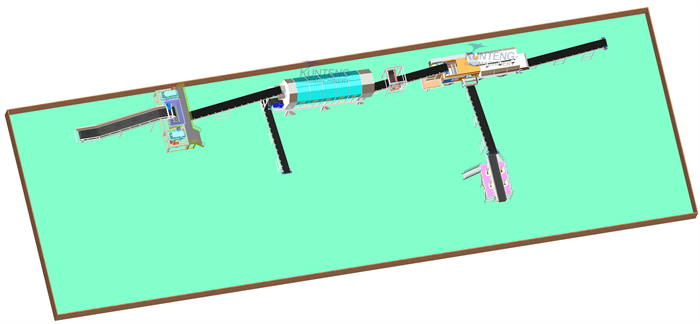

2.Shredder Application Field

Shredders are used across various industries and sectors for a range of purposes, mainly to break down materials into smaller, more manageable pieces. This process is typically used for recycling, waste reduction, and material preparation for further processing. Below are the primary application fields for shredders:

1. Waste Management & Recycling

2. Industrial Waste Management

3. Food Processing

4.Agriculture & Farming

5. Construction and Demolition

6. Textile Industry

7.Energy & Biomass Production

8.Automotive Industry

9.Security and Data Protection

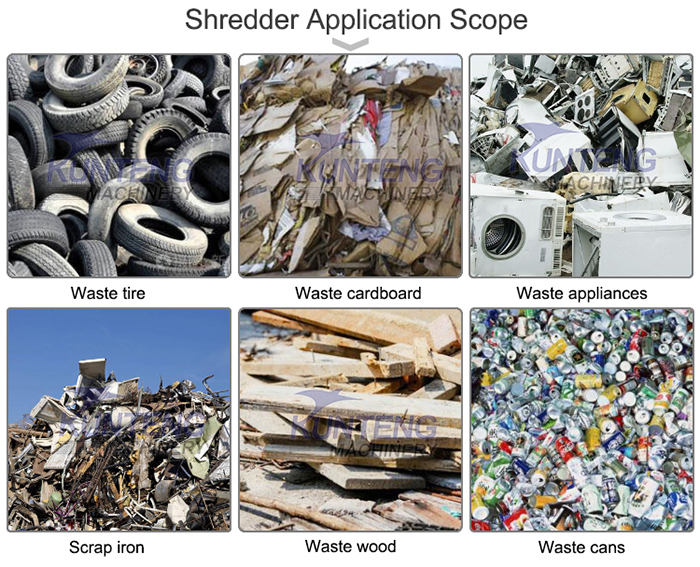

3.Main equipment in the production line

4.Customer cases

Many customer cases show how industrial garbage shredder production line plays an essential role in waste reduction, recycling, security, and material processing across diverse industries. Whether for industrial, environmental, or commercial purposes, industrial waste shredder production line helps make materials easier to manage, recycle, or repurpose.Our industrial garbage shredding and sorting line has exported to many countries.Welcome to cooperate and discus!