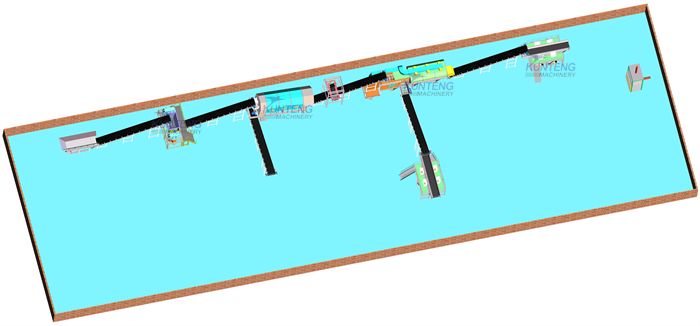

Depending on the type of waste and its intended end-use, additional processing might be required. This could include fine shredding, grinding, or even washing the materials to prepare them for specific recycling streams (e.g., plastic washing for reprocessing).

3.Typical Waste Types Handled:

1)Municipal Solid Waste (MSW):

2)Industrial Waste:

3)Electronic Waste (E-Waste):

4)Construction and Demolition Waste:.

5)Plastic and Rubber Waste:

6)Organic Waste:

4.Benefits of a Solid Waste Shredding Production Line:

Volume Reduction: Shredding significantly reduces the volume of waste, making it easier to transport, store, and recycle.

Resource Recovery: The separation of valuable materials like metals, plastics, and paper makes it easier to recycle and recover resources, promoting a circular economy.

Cost Efficiency: By reducing waste volume, companies can save on disposal costs. Additionally, recovered materials can be sold, providing economic value.

Environmental Impact: Properly recycling and processing waste helps divert material from landfills, reducing environmental pollution and conserving natural resources.

Automation: A solid waste shredding production line is highly automated, reducing the need for manual labor and improving the efficiency of waste processing.

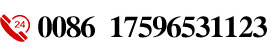

5.Whole working process of solid waste shredding production line

A solid waste shredder production line is a critical component of modern waste management systems, providing a solution to process various types of waste efficiently. The municipal solid waste shredder production line is the first step in a complex recycling and waste-to-resource chain, helping companies manage waste, recover valuable materials, and contribute to sustainability.Welcome to our factory to inspect our solid waste shredding and sorting production line.