Bouncing screening machine, also known as bouncing screen, bounce screen, etc. Bouncing screen grading is a new type of screening machine specially developed for garbage ...

Phone:0086 17596531123

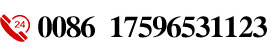

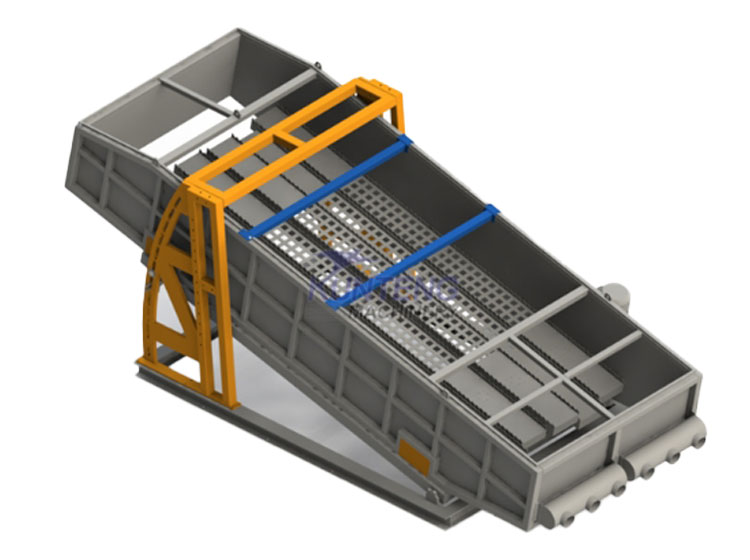

Bouncing screening machine, also known as ballistic screen, 3D bouncing screen, etc. Bounce screen is a new type of screening machine specially developed for garbage sorting and processing. Its principle is to separate each other by moving on or colliding with the inclined surface according to the differences in size, density, and shape of different components in the sorted materials. It is commonly used in industries such as sorting household waste, pre selected decoration waste, pressed kitchen waste, paper recycling, etc.

1、Working principle

The bouncing screen drives the sieve plate to move up and down forward and backward through an eccentric shaft (crankshaft gear, etc.), causing the solid waste on the sieve plate to be shaken and scattered into heavy, rolling 3D material parts (such as plastic bottles, wood, cans, etc.) and light, flat 2D material parts (film, paper, cardboard) and undersized material parts (sand, food residue), facilitating subsequent processing.

Based on the characteristics of bounce screens and the complex nature of solid waste in China, they are mainly used in front-end pre sorting systems for construction and decoration waste, light materials from municipal solid waste incineration slag, and some industrial waste sorting systems;

Under the action of the driving motor, the bouncing screening machine forms a parallel four-bar mechanism by connecting the active and passive transmission mechanisms composed of active shaft, passive shaft, eccentric wheel (crankshaft, chain and other transmission devices) with the support seat and screen plate. The screen plate produces a reciprocating circular motion similar to bouncing, separating the material input from the feeding port into three types: 3D materials with large particle size and good rebound effect, 3D materials with small particle size and poor rebound effect, 2D materials with large particle size and poor rebound effect, flat and lightweight, which are respectively received by three discharge hoppers.

According to the different climbing and bouncing abilities of different materials, the screening process will be affected by the tilt angle. Therefore, the hydraulic lifting system is used to adjust the angle between the box and the sieve plate as a whole to achieve the adjustment of the bouncing lifting angle of the sorted materials.

3D object: refers to heavier, rolling materials such as plastic bottles, stones, wood, boxes, cans, etc;

2D object: refers to lighter, sheet-like materials such as plastic film, packaging bags, paper, cardboard boxes, fiber products, etc;

Fine matter: refers to the screened material, such as sand, stones, organic matter, etc.

Henan Kunteng Machinery Manufacturing Co., Ltd

Address:No. 9 Yulian Industrial Cluster, Gongyi, Zhengzhou, Henan Province China

Phone:0086 17596531123