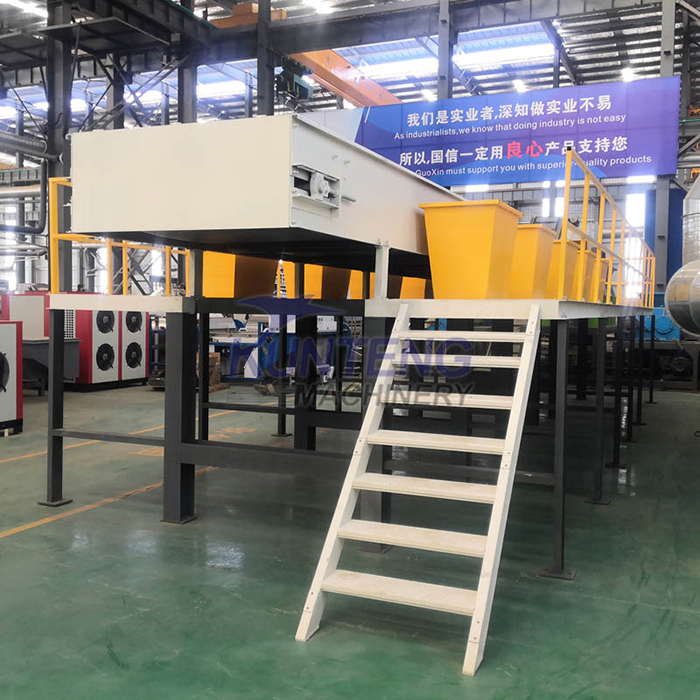

The manual sorting platform is an indispensable process in the waste management equipment system. The manual sorting station is mainly used for the parts of the garbage processing line that cannot be sorted by machinery and is generally used to sort out large interference before the trommel screen.

The sorting workers carry out garbage sorting operations in the spacious and bright sorting room. The sorting platform is equipped with good ventilation and air conditioning devices to ensure the sorting personnel operate in a good working environment.

At the end of the feeding system, there is a manual sorting platform where workers will pick up the large solid wastes, such as quilts, tree trunks, long sticks, brick stones, etc.

In fact, we design a variety of manual sorting platforms in the whole waste sorting line, which can improve the separation rate and prolong the service life. After that, there is a bag breaker to tear the bags automatically to improve working efficiency.

3、Features of Manual Sorting Platform

Fresh air ventilation air conditioner: The fresh air ventilation systemis provided in the sorting room, which can provide fresh air, and can create sterilization and negative oxygen conditions. The air outlet of the fresh air ventilation system is set directly above each manual sorting station in the manual sorting room. This treatment effect will be more significant and the working environment of the operator will be better.

Sorting belt conveyor: There is a horizontal material transmission belt conveyor in the center of the sorting room, which is convenient for manual sorting; the width of the conveyor can be designed according to the processing volume and the average height of the operators. The width of the conveyor must not be too wide, otherwise, it will affect the sorting effect of the items.

Sorting room: Thermal insulation, spacious and bright, provide a comfortable working environment for sorting personnel. The room is equipped with a number of spacious and bright glass windows. In the sorting room where the personnel are too concentrated, at least two external doors are required. The sorting platform can be designed as a concrete structure or as a steel structure platform with anti-skid pattern plates laid on it. The design load-bearing requirements can bear the weight of conveyor equipment, sorting workers, and maintenance personnel,.

Material receiving layer of the sorting room: It is the bottom of the sorting room, and can be equipped with a garbage receiving container or other material receiving device.

4、Parameter of Manual Sorting Platform

| Model |

GX-B800 |

GX-B1200 |

Conveyor

|

Weight material conveyor

|

Light material conveyor

|

| Dimension(mm) |

800×10000 |

Dimension(mm) |

1200×10000 |

| Power |

4kw |

Power |

7.5kw |

Sorting platform

|

Four-person sorting satation |

Ten-person sorting satation |

| Dimension(mm) |

800×8000 |

Dimension(mm) |

1200×13000 |

| Power |

4kw |

Power |

7.5kw |

| Sorting conveyor |

Dimension(mm) |

800×8000 |

Dimension(mm) |

1200×13000 |

| Working platform dimension |

7000×1000×1000mm |

12000×1000×1000mm |

| Bottomless trash can |

4 |

10 |

| Removable trash can |

2 |

5 |