Construction waste sorting machine is an environmentally friendly equipment.Construction waste sorting equipment aims to realize the resource utilization.The construction...

Phone:0086 17596531123

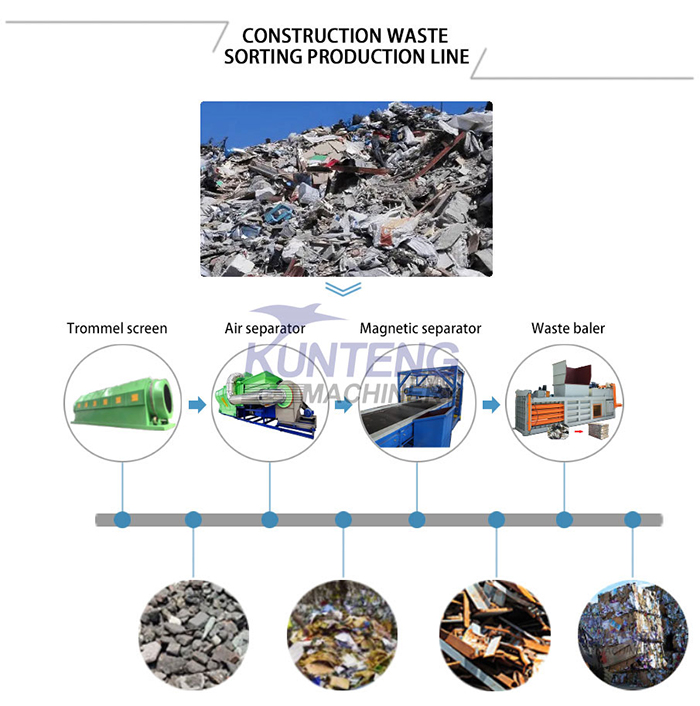

The construction waste sorting and crushing line is an automated production line for efficient treatment of construction waste. It can effectively separate the different components in construction waste and convert them into valuable renewable resources through crushing, screening and other processes. The following is a detailed introduction to the construction waste sorting and crushing line:

1. Composition and working principle

The construction waste sorting and crushing line is usually composed of multiple modules such as pretreatment system, sorting system, crushing system, screening system, magnetic separation system, wind selection system, dust removal system and intelligent control system.

Pretreatment system: Preliminary removal of large debris by manual or mechanical means to lay the foundation for subsequent automated processing.

Sorting system: Use equipment such as vibrating screens and drum screens to perform preliminary separation according to material size and shape, and combine manual picking to further improve the sorting accuracy.

Crushing system: Use jaw crushers, impact crushers and other equipment to crush large pieces of material to a suitable particle size for subsequent processing and resource utilization.

Screening system: Use circular vibrating screens, linear vibrating screens, etc. to subdivide materials according to particle size to meet the needs of different resource utilization.

Magnetic separation system: Use magnetic separators to remove ferrous metals and realize the recycling of metal resources.

Wind selection system: Use airflow and gravity to separate light materials (such as plastics and paper) from heavy materials (such as concrete blocks).

Dust removal system: equipped with bag dust collector, cyclone dust collector, etc., to effectively collect dust generated during the production process and reduce environmental pollution.

Intelligent control system: integrated with PLC control, remote monitoring and other technologies to achieve automated operation and intelligent management of the production line.

2. Application scenarios

Construction waste sorting and crushing lines are widely used in the treatment of various types of construction waste, including but not limited to:

Construction sites: treatment of construction waste generated during the construction process, such as concrete blocks, bricks and tiles, wood, steel bars, etc.

Demolition sites: treatment of waste generated during the demolition process, such as old building components, doors and windows, pipes, etc.

Urban waste treatment centers: treatment of construction waste generated during urban renewal and transformation to achieve resource reuse.

3. Advantages and significance

Efficient processing: The construction waste sorting and crushing line can efficiently process a large amount of construction waste, improve processing efficiency, and reduce the time of garbage accumulation.

Resource recovery: Through sorting and crushing, valuable resources such as metals, wood, concrete blocks in construction waste can be effectively recycled to achieve resource reuse.

Environmental protection and energy saving: The effective operation of the dust removal system greatly reduces dust emissions in the production process, which meets the requirements of energy conservation and emission reduction.

Economic benefits: The sorted materials of different materials can be reused as renewable resources, bringing economic benefits to the enterprise.

Social benefits: The application of the construction waste sorting and crushing line helps to reduce the amount of landfill and incineration, reduce pollution to the environment, enhance the image of the city, and promote the sustainable development of the city.

4. Practical cases

There have been many successful cases of construction waste sorting and crushing lines at home and abroad. For example, a certain city's construction waste resource utilization project has introduced an advanced sorting and crushing line to process hundreds of thousands of tons of construction waste annually, achieving a resource utilization rate of more than 90% and achieving significant economic and social benefits. benefit.

In summary, the construction waste sorting and crushing line has significant advantages and significance in processing construction waste. With the continuous advancement of technology and continued policy support, construction waste sorting and crushing lines will become more intelligent and efficient, making greater contributions to sustainable urban development and resource conservation and utilization.

We have hosted clients from over 100 countries and regions, highlighting your company’s global reach and appeal. This experience can provide you with valuable insights into different markets and help you build a strong international presence.Our construction waste sorting machine, construction waste sorting equipment, construction garbage disposal equipment,etc. are recognized and selected by many customers If you need any advice on expanding into new regions or optimizing your global operations, feel free to ask!

Henan Kunteng Machinery Manufacturing Co., Ltd

Address:No. 9 Yulian Industrial Cluster, Gongyi, Zhengzhou, Henan Province China

Phone:0086 17596531123