The stale garbage separator machine use the automated and intelligent control technology.The stale waste screening machine can be customized.The stale waste treatment mac...

Phone:0086 17596531123

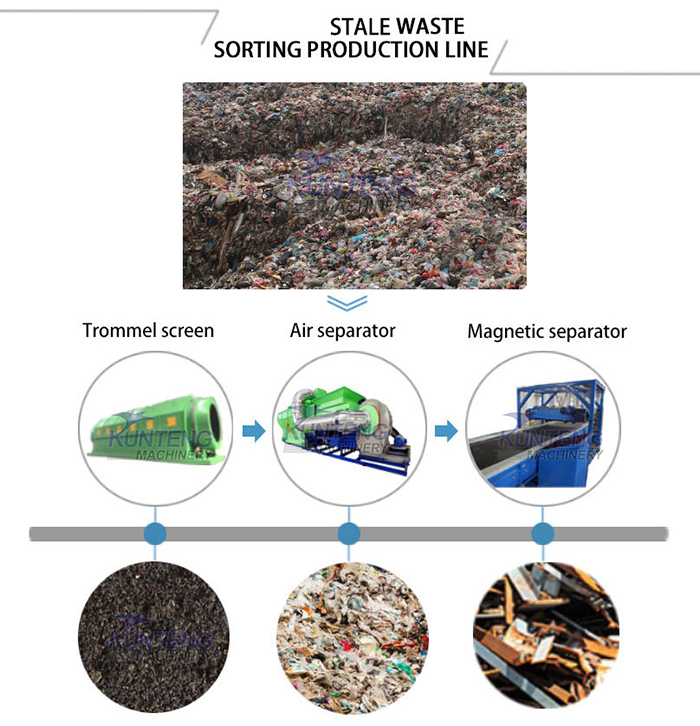

The stale garbage sorting production line is a comprehensive production line that integrates crushing, screening, sorting, biological treatment and resource utilization. It aims to efficiently and environmentally treat stale garbage formed after long-term landfill. The following is a detailed introduction to the stale garbage sorting production line:

1. Production line composition

The stale garbage sorting production line is mainly composed of the following key equipment:

Crusher: used to break large pieces of stale garbage into smaller particles for subsequent processing.

Screening machine: using equipment such as vibrating screens and drum screens to separate garbage into different categories according to particle size, laying the foundation for subsequent sorting work.

Magnetic separator: using magnetic fields to separate iron-containing metals to achieve recycling of metal resources.

Wind separator: using wind power to separate light materials (such as paper and plastics) from heavy materials (such as stones and soil), further improving sorting efficiency.

Photoelectric sorter: using optical technology to distinguish different types of plastics or other materials to achieve more refined classification.

Biological treatment facilities: for organic waste, biological treatment methods such as composting or anaerobic digestion are used to convert it into organic fertilizer or biomass energy.

2. Process flow

The process flow of the stale garbage sorting production line usually includes the following steps:

Garbage collection and transportation: Special transportation vehicles collect stale garbage and transport it to the treatment plant.

Pretreatment: The garbage is crushed to a certain size by a crusher for subsequent treatment. At the same time, large pieces of debris and non-recyclable materials are removed.

Screening and sorting: Use screening machines and sorting equipment to classify garbage according to particle size, material and other characteristics to separate recyclable materials and organic materials.

Biological treatment: Composting or anaerobic digestion of organic waste is carried out to convert it into organic fertilizer or biomass energy.

Resource recovery: Further processing of the sorted recyclable materials, such as compression and packaging, cleaning and crushing, etc., for subsequent resource utilization.

Final disposal: The sorted materials are recycled or safely disposed of, such as metal recycling and reuse, organic fertilizer for agricultural production, etc.

3. Key technologies

The stale garbage sorting production line relies on the application of multiple key technologies, including:

Physical sorting technology: effectively separate different types of garbage through conveyor belts, wind sorting, magnetic sorting and other means.

Mechanical sorting technology: use automated equipment and intelligent control systems to improve sorting efficiency and accuracy.

Biological treatment technology: use composting or anaerobic digestion to convert organic waste into organic fertilizer or biomass energy.

Resource recovery technology: further process the sorted recyclable materials to achieve resource reuse and recycling.

4. Advantages and Features

High Efficiency: The use of automated and intelligent control technology improves sorting efficiency and accuracy, reduces manual participation, and reduces labor intensity.

Environmental Protection: The exhaust gas treatment system strictly controls the emissions of the production line, reduces environmental pollution, and meets environmental protection requirements.

Resource Utilization: Effectively separate recyclable materials, improve resource utilization, and realize the resource utilization of garbage.

Flexibility: The production line can be customized according to the garbage composition and processing requirements of different regions, with strong adaptability and flexibility.

5. Application prospects

The stale garbage sorting production line has broad application prospects in the field of environmental protection. With the acceleration of urbanization and the continuous increase in the amount of garbage, the requirements for garbage treatment technology are getting higher and higher. As an efficient and environmentally friendly garbage treatment technology, the stale garbage sorting production line not only helps to solve the problem of garbage siege, but also realizes the recycling of resources and promotes sustainable development. In addition, the production line can also be widely used in urban garbage treatment centers, resource recovery bases and other places to contribute to the cause of environmental protection.

In summary, the stale garbage sorting production line is an efficient and environmentally friendly garbage treatment facility with broad application prospects and important environmental significance.

6.Customer site

This is our waste sorting customer site in the Philippines

Henan Kunteng Machinery Co.,Ltd.was established in 1999.We are engaged in manufacturing stale garbage separator machine, stale waste screening machine, stale waste treatment machine,etc for more than 20 years.

Our mature equipment include trommel screen machine, air separation machine, magnetic separators, garbage bag breaking machine, waste shredder machine, manual sorting tables, waste baling machine, chain plate feeder, belt conveyor.etc.We can design the most reasonable solution for customers. Welcome to our factory to discuss cooperation.

Henan Kunteng Machinery Manufacturing Co., Ltd

Address:No. 9 Yulian Industrial Cluster, Gongyi, Zhengzhou, Henan Province China

Phone:0086 17596531123