Recently, with the growth of industrial production and resource recovery demand, drum screen as a key screening equipment, has received more attention. So, how does the drum screen work, and what materials can be screened out?

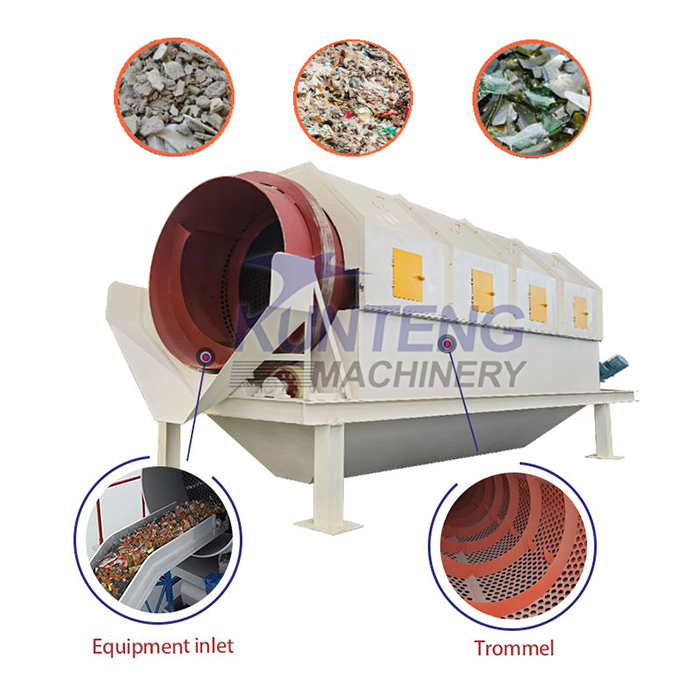

The drum screen is mainly composed of a cylindrical sieve barrel, a driving device, a feeding and discharging device, etc. When working, the motor drives the sieve cylinder to rotate, and the material to be screened enters the sieve cylinder from the feed port. In the process of rotating the sieve cylinder, the material particles smaller than the size of the sieve hole fall through the screen and become the material under the screen; The material larger than the size of the screen is moved along the axis of the screen cylinder, and eventually discharged from the discharge port to become the material on the screen. The whole screening process is continuous and efficient, and can effectively separate materials of different particle sizes.

In the construction industry, it can screen sand, construction waste, etc., and separate aggregates that meet different particle size requirements for concrete production, road laying, etc. In the treatment of domestic waste, it can also help to separate the waste components of different particle sizes, and help the subsequent classification, recycling and treatment.

Kunteng machinery specializes in the production and development of garbage disposal equipment. If you need a roller screen, please feel free to contact us.

The garden waste shredding RDF briquetting line provides an efficient and enviro...

The scrapped car shredding line, with the help of professional equipment, provid...

Kunteng Machinery relies on professional technology and innovative combustible w...

Henan Kunteng Machinery Manufacturing Co., Ltd

Address:No. 9 Yulian Industrial Cluster, Gongyi, Zhengzhou, Henan Province China

Phone:0086 17596531123